Zoom- lowering gunnels

Moderators: kenneth, sbroam, TheKrikkitWars, Mike W., Sir Adam, KNeal, PAC, adamin

- sbroam

- CBoats.net Staff

- Posts: 3969

- Joined: Thu Nov 07, 2002 2:12 am

- Location: Lexington, SC

- Contact:

I'm thinking of doing that to my Zephyr because it gets so much danged water *in* the vinyl gunwales.

C-Boats Moderator

http://picasaweb.google.com/scott.broam/CanoeOutfitting

http://picasaweb.google.com/scott.broam/CanoeOutfitting

SW,

I used #8 x 1 1/4" stainless woodscrews to attach the gunwhales. They are recessed about 1/8" - give or take a 1/16 on some...haha - and go from inside to outside, through the ABS and through both sections. Screw spacing is 5" center to center. (I pulled a spare screw from my workbench area, and I am pretty sure they are #8...)

My deckplates are a little odd, and I don't know if I would exactly repeat the process, but I felt a little restrained based on the Viper's dive to the bow/stern several inches from the ends of the boat. Deckplates are also Ashe.

Steve

I used #8 x 1 1/4" stainless woodscrews to attach the gunwhales. They are recessed about 1/8" - give or take a 1/16 on some...haha - and go from inside to outside, through the ABS and through both sections. Screw spacing is 5" center to center. (I pulled a spare screw from my workbench area, and I am pretty sure they are #8...)

My deckplates are a little odd, and I don't know if I would exactly repeat the process, but I felt a little restrained based on the Viper's dive to the bow/stern several inches from the ends of the boat. Deckplates are also Ashe.

Steve

This was one, with a strange but effective method... http://cboats.net/cforum/viewtopic.php?t=6471sbroam wrote:I've thought about putting a rather small outwale on so there is less to catch on rocks, tcs. Then couple that with a much beefier inwale to provide strength and have more material to hang thwarts from. It would make it harder to dump dry, though, so you might cut some slots for draining. Phil posted (or e-mailed?) his method for attaching thwarts that was interesting, too.

It has dramatically reduced failure, associated with wear and tear. Of course catastrophic failure is always a possibility.

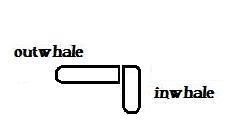

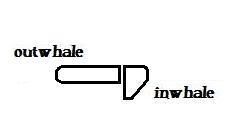

I also like to either turn the inwhale flat to minimized water retention, or better yet shape something like this second one:

(it also helps with keeping the screw inside the wood, and not drilling out... as you are drilling and using a shorter screw.)

I screw from the inside, until unable to on the ends.

at the expense of being redundant (if you read the other link)...

One thing that really helps with gunwhale longevity, is to consider thwart placement first. When screwing them together the easy thing is to start at one end, and not stop until finished. However this almost invariably results in having a thwart bolt and gunwhale screw in close proximity. In my experience, this will likely be a future spot of failure/breakage. It is well worth the trouble to tape the spot, where thwarts are to be attached, and then re-consider your screwing pattern. If the thwart bolts and gunwhale screws are keep fairly far apart, the wear and tear on gunwales will definitely decrease. Two holes one inch apart will break, especially if one is drilled top-2-bottom and the other side-to-side. As not only is wood drilled out in two opposing directions, but you also lose a substantial portion of wood (strength) when countersinking the screw heads. Yes - under undue stress wood will fail, however in my experience this is where they will fail first. And secondly anywhere two holes are drilled in close proximity. Carefully limiting the number of holes, and planning where to drill will definitely help.

I initially in the beginning, started out just marking a distance (maybe) every six inches, and just going for it. Now I mark thwart locations, and then center in-between a certain number of screws. Not only does it make for a longer lasting job, but it pays off in looks. The result is a neat clean looking finish... which most likely no one else will notice.... but at least they'll notice it longer.

One thing that really helps with gunwhale longevity, is to consider thwart placement first. When screwing them together the easy thing is to start at one end, and not stop until finished. However this almost invariably results in having a thwart bolt and gunwhale screw in close proximity. In my experience, this will likely be a future spot of failure/breakage. It is well worth the trouble to tape the spot, where thwarts are to be attached, and then re-consider your screwing pattern. If the thwart bolts and gunwhale screws are keep fairly far apart, the wear and tear on gunwales will definitely decrease. Two holes one inch apart will break, especially if one is drilled top-2-bottom and the other side-to-side. As not only is wood drilled out in two opposing directions, but you also lose a substantial portion of wood (strength) when countersinking the screw heads. Yes - under undue stress wood will fail, however in my experience this is where they will fail first. And secondly anywhere two holes are drilled in close proximity. Carefully limiting the number of holes, and planning where to drill will definitely help.

I initially in the beginning, started out just marking a distance (maybe) every six inches, and just going for it. Now I mark thwart locations, and then center in-between a certain number of screws. Not only does it make for a longer lasting job, but it pays off in looks. The result is a neat clean looking finish... which most likely no one else will notice.... but at least they'll notice it longer.

Last edited by philcanoe on Fri Feb 19, 2010 6:43 pm, edited 1 time in total.

Re: WOOZ

(per WATCO oiling) This will probably open up another can of worms, but...

Ideally to me (IMHOpinion) the very best method is to oil a couple times, like over days... and then set aside for a few weeks for oil to completely soak in. So that after attachment is complete, you can then apply a coat (or two) of either a spar varnish, a polyurethane varnish, or a spar polyurethane varnish. In this manner you get the benefits of penetration (from oil) and the long lasting protection of a coating. Which is beneficial because as varnishes inevitably craze, the wood still is protected by those underlaying oils. The trick is to allow (whichever chosen) oil adequate drying time, before painting on any varnish.

There is some debate about varnishes holding or trapping moisture... however based on the left to rot (in the backyard) method... the longest lasting have been those that were varnished (hands down-not even close). In one such instance a discarded (ie. broken worn out) boat over it's lifetime had one side that was varnished, and other side replaced without varnishing. Over several years the one unvarnished side ended up in black bit's an pieces, and in some places just screws left in the hull. While the other while still trashed out, had structural strength, was resistant to breakage, and looked like wood (as opposed to black rot). Albeit there were places, where water had gotten inside and rotted out even on the varnished side, where the outside crumbled inward when folded.

I believe for the purist Spar Varnish is the choice, as it has a more traditional aesthetic look. As if restoring an vintage piece of furniture, runabout, or canoe. However I go with the newer high tech, urethane varnishes, as my boats are not really show pieces, but show off in pieces . There is the matter of varnish getting into the slots on the screw head, but that means you've covered up a place of water infiltration...

. There is the matter of varnish getting into the slots on the screw head, but that means you've covered up a place of water infiltration...

Now with that said... I usually oil and go, since it's a performed in haste project. And usually apply after attaching; however always applying a bit behind the gunwhale before screwing, as this is the last chance to get to it. In a perfect world I would have kept a couple different sized precut ready to go pieces, oiled, and ready to go. But just having a long piece of 'good' ash laying around was enough.

Thank you - LORD, for plastic canoes....

Ideally to me (IMHOpinion) the very best method is to oil a couple times, like over days... and then set aside for a few weeks for oil to completely soak in. So that after attachment is complete, you can then apply a coat (or two) of either a spar varnish, a polyurethane varnish, or a spar polyurethane varnish. In this manner you get the benefits of penetration (from oil) and the long lasting protection of a coating. Which is beneficial because as varnishes inevitably craze, the wood still is protected by those underlaying oils. The trick is to allow (whichever chosen) oil adequate drying time, before painting on any varnish.

There is some debate about varnishes holding or trapping moisture... however based on the left to rot (in the backyard) method... the longest lasting have been those that were varnished (hands down-not even close). In one such instance a discarded (ie. broken worn out) boat over it's lifetime had one side that was varnished, and other side replaced without varnishing. Over several years the one unvarnished side ended up in black bit's an pieces, and in some places just screws left in the hull. While the other while still trashed out, had structural strength, was resistant to breakage, and looked like wood (as opposed to black rot). Albeit there were places, where water had gotten inside and rotted out even on the varnished side, where the outside crumbled inward when folded.

I believe for the purist Spar Varnish is the choice, as it has a more traditional aesthetic look. As if restoring an vintage piece of furniture, runabout, or canoe. However I go with the newer high tech, urethane varnishes, as my boats are not really show pieces, but show off in pieces

Now with that said... I usually oil and go, since it's a performed in haste project. And usually apply after attaching; however always applying a bit behind the gunwhale before screwing, as this is the last chance to get to it. In a perfect world I would have kept a couple different sized precut ready to go pieces, oiled, and ready to go. But just having a long piece of 'good' ash laying around was enough.

Thank you - LORD, for plastic canoes....

If immediately pre-oiled they would be real hard to work with, but ones that have been oiled, re-oiled, (and even re-oiled) then left to dry are not bad. When oiling (per instruction on can) you wait so long, wipe off excess, set aside for a while, then redo...

The waiting is key, and why on a hurry job (as in need a boat fast) I only oil the backside once, wait a little while, and get the boat back ready to go.

Another reason why a really good gunwhale job cost so much, the man-hours start to add up.

The waiting is key, and why on a hurry job (as in need a boat fast) I only oil the backside once, wait a little while, and get the boat back ready to go.

Another reason why a really good gunwhale job cost so much, the man-hours start to add up.

- Mr.DeadLegs

- CBoats Addict

- Posts: 435

- Joined: Wed Feb 14, 2007 8:31 pm

- Location: Marietta, Georgia

Is there any reason not to dry fit everything, holes drilled, screws run in about 3/4 way in etc. Then disasemble, preoil, assemble then finish?

"Life's journey is not to arrive at the grave safely in a well preserved body, but rather to slide in sideways totally worn out, shouting "Holy large steaming pile of dog doo what a Ride" " Nolan Whitesell

not sure about relining up the holes... it's hard sometimes to just get both the same height. Have used a drill press to counter sink (not sunk) holes on screwing in-from side.. That worked really well, however still drilled matching (other side) screw hole after c-clamping. Can't really say though... Test and report time?

Last edited by philcanoe on Mon Feb 22, 2010 11:27 am, edited 1 time in total.

- sbroam

- CBoats.net Staff

- Posts: 3969

- Joined: Thu Nov 07, 2002 2:12 am

- Location: Lexington, SC

- Contact:

I've thought if I ever was going to do a bunch of gunwales, I'd take some three inch PVC, build up a 16-17' long section, cap one end, and put a threaded cap on the other. I'd put the gunwales in there and a gallon of Watco oil and soak them. If turning it everytime I walked by wasn't enough, I'd rig up something to roll it real slow. A couple of days of that ought to get maximum penetration?

C-Boats Moderator

http://picasaweb.google.com/scott.broam/CanoeOutfitting

http://picasaweb.google.com/scott.broam/CanoeOutfitting

- Smurfwarrior

- C Maven

- Posts: 1491

- Joined: Mon Dec 14, 2009 3:09 am

- Location: Utah